Warehousing is king 👑

Warehouses and fulfillment centers have been the nervous system of the global economy since the Covid-19 pandemic stroke in early 2020. As consumption moved massively online, brands and retailers understood that the new battleground for winning customers satisfaction and retention was the delivery experience. We cannot blame only Covid-19 for this. Since its inception, Amazon has been raising the bar in term of customer expectations, with at least next-day delivery for Prime-labelled products being today the norm in most urban agglomerates. Storing and fulfillment represents a key link of the delivery value chain and good a potential candidate for becoming its bottleneck. Thus, we decided to investigate whether venture capitalists should seize the momentum and fuel the next generation of warehousing and fulfillment technologies and business models.

Automate, automate, automate! 🦾

Facts

Automation of warehousing and fulfillment operations has just started. It is estimated that by 2025, more than 4 million commercial robots will be installed in over 50,000 warehouses, up from just under 4,000 robotic warehouses in 2018.

Labor costs could account up to 35% of warehousing and fulfillment costs in Europe, with picking being by far the costliest operation. Renting the facility does not exceed, usually, 30% of the total costs.

The recent spike in quick-commerce startup allowed for a new type of warehouse to emerge: the city hub – a small warehouse located in urban areas that allows faster delivery times. These city hubs are usually costlier to maintain, thanks to the higher rent and wages that need to be paid in city centers.

Aster’s view

The coming years will know a great wave of warehouse automation. As logistics and fulfillment market expand thanks to e-commerce growth, the need for a more efficient and productive delivery infrastructure will intensify. We believe that automation needs will be even stronger in urban warehouses, where operating costs are higher – and thus saving potentials are greater.

Let’s re-engage warehouse workers 👷♀

Facts

Following the recent spike in demand of warehouse associates, attracting new workers and retaining existing ones is becoming more and more difficult, especially in the North American and European markets, where many organizations’ annual turnover rate exceeds 100%. It is no secret that the job is highly repetitive and physically demanding.

Amazon is trying to make the job less tedious through gamification: workers can compete in various games by completing warehouse tasks and can win digital rewards, such as virtual pets 🐶 and real-world items.

It is estimated that in less than 4 years, 75% of the workforce will be represented by Millennials, the first generation that grew up with digital technology at their fingertips. However, the penetration of digital tools among warehouse workers is low, and processes are either paper-based or reliant on legacy software with awful UX.

Aster’s view

In the fight for talent, employers will understand the need to make the warehouse routine more engaging and the work environment safer.

Frontline workers will benefit from a wave of digitalization thanks to modern productivity software and it is likely that if the Amazon gaming experiment succeeds, other employers will follow the delivery giant example.

To make the warehouse associates work less dangerous and tiring, exoskeletons and other wearables, if they will gain acceptability among the workforce, by essentially being more comfortable to wear, could represent a solution.

Warehousing-as-a-Service is booming 💻

Facts

Companies are more and more selling services, rather than just products. Consumers today can subscribe to pretty much everything you can think of: music, video streaming, cars or even just… pickles! 🥒 This paradigm shift has approached the logistics world as well, with a growing number of companies offering flexible warehousing space in different locations to brands and retailers in return of a monthly subscription fee that depends on the capacity used and on the number of orders fulfilled.

Aster’s view

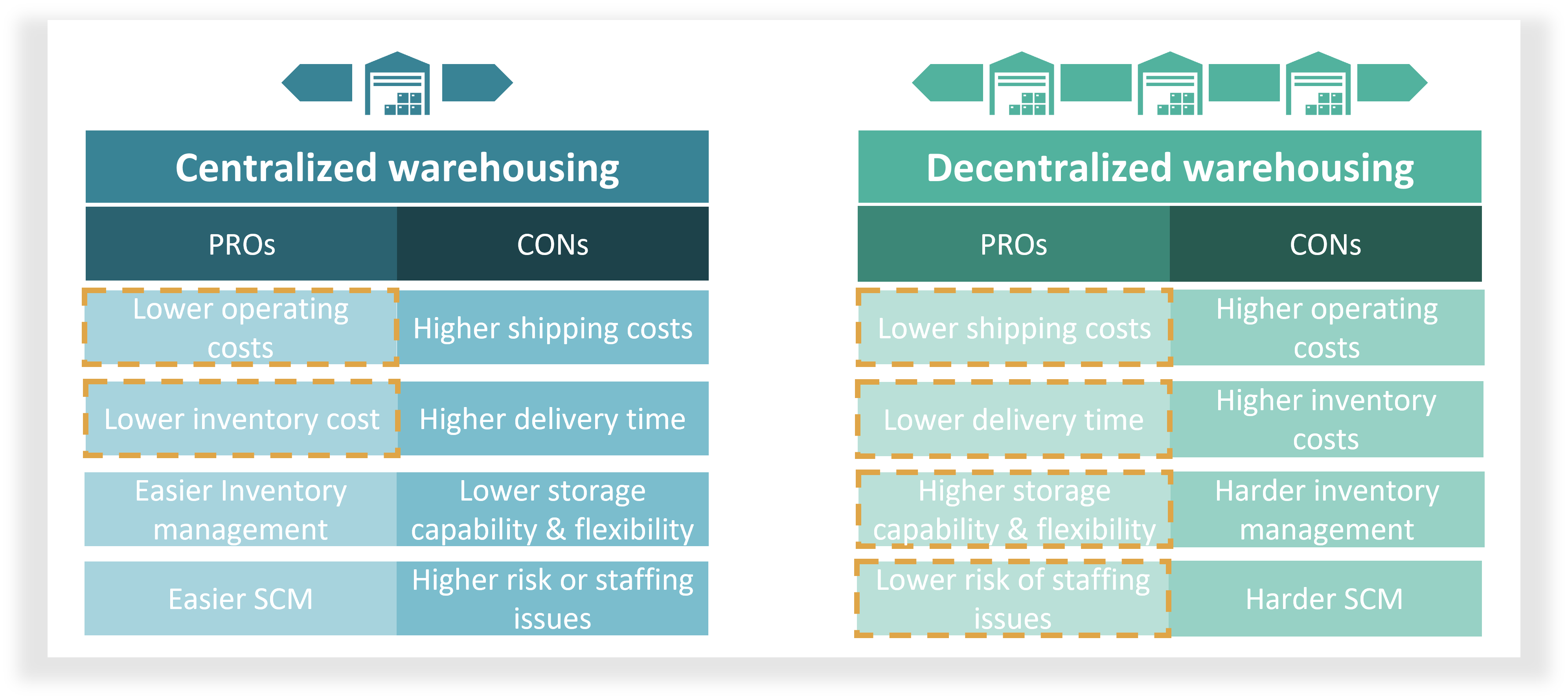

Source: Aster

Warehousing and fulfillment-as-a-Service is a winning formula, which brings all the benefits of decentralized warehousing, without its major drawbacks (higher operating and inventory cost). In fact, thanks to a network of geographically distributed warehouses, shippers can:

- lower shipping costs and delivery time by storing their products closer to their customers;

- expand storage capacity without the need to build or lease new infrastructure, but simply by upgrading their subscription;

- mitigate the risk of labor shortage, by having inventory distributed in different locations.

At Aster, we strongly believe in the widespread adoption of this model in Europe in the coming years (as it already happened in the US).

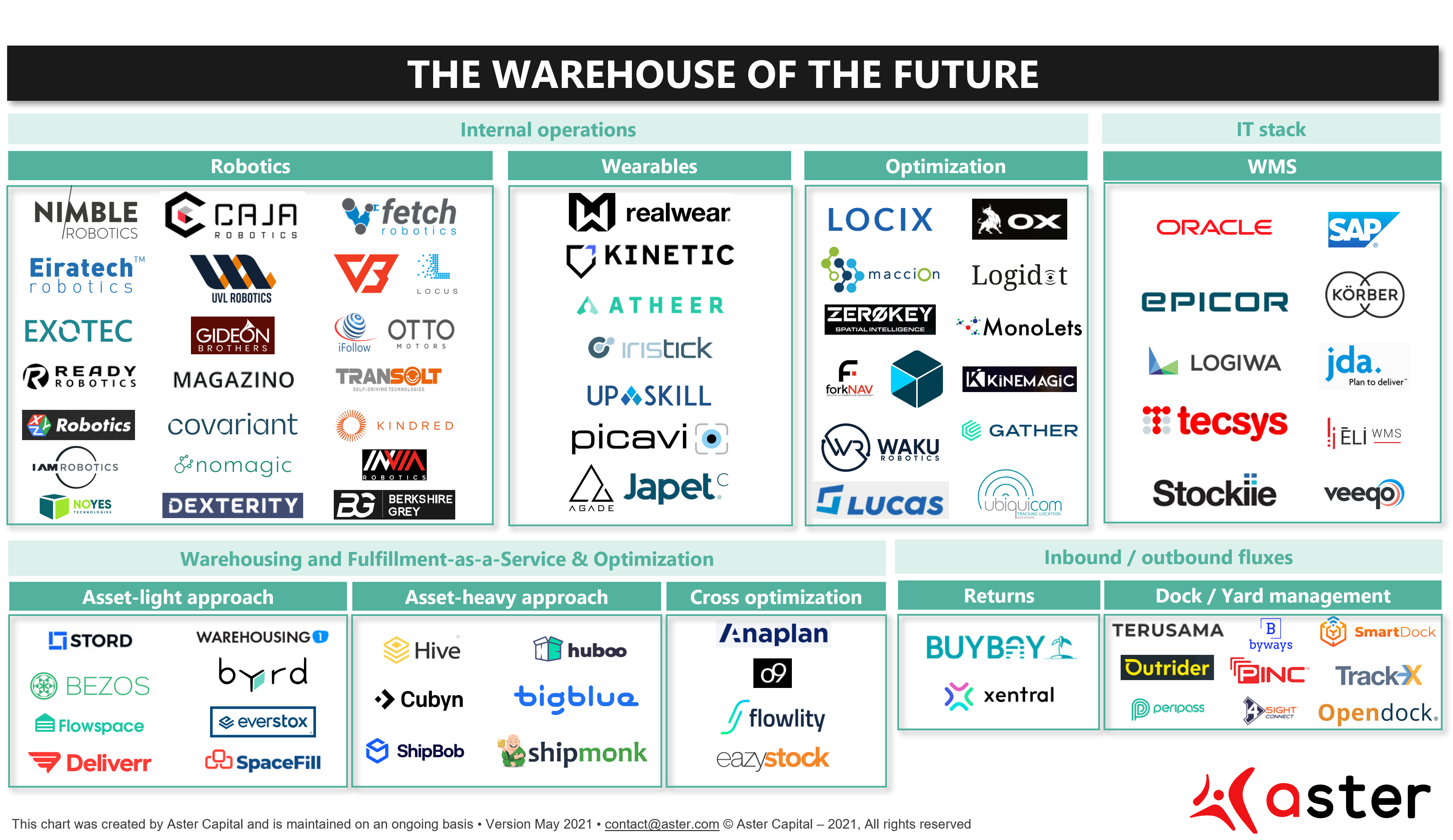

Want to know more about which companies are shaping the warehouse of the future? ⤵

Source: Aster

For founders

Hey you! If the vision shared in this article resonates with you or you are out there building the future of warehouses 🦄, ping me on LinkedIn 📩.