If there is one silver lining from the pandemic, it is that it helped to reveal the vulnerabilities in global supply chains on a scale never before experienced. As China produces 20% of global goods, the impact on global trade has been devastating and was compounded by the European lockdown: 14.8% decline in transaction volume in Q2 compared to Q1 2020. Players have been forced to reinvent their supply chains, which has boosted the adoption of supply chain risk management and procurement solutions.

Supply chains were already undergoing huge transformations before the pandemic. In the context of globalization, large companies had redesigned their processes to increase flexibility and reduce costs. But the pandemic revealed the weaknesses of such a system:

- Fragmentation of supply chains, leading to more complex patterns, communication issues and greater exposure to risk

- High vulnerability to supply and demand shocks due to the lean manufacturing strategies that involve minimizing the amount of inventory

- New customer expectations demanding higher environmental, social and transparency standards

Despite this huge disruption, Covid-19 has also accelerated some trends and created new business opportunities. According to Gartner, at least 50% of the world’s leading companies will be using AI, advanced analytics and IoT in their supply chain operations by 2023.

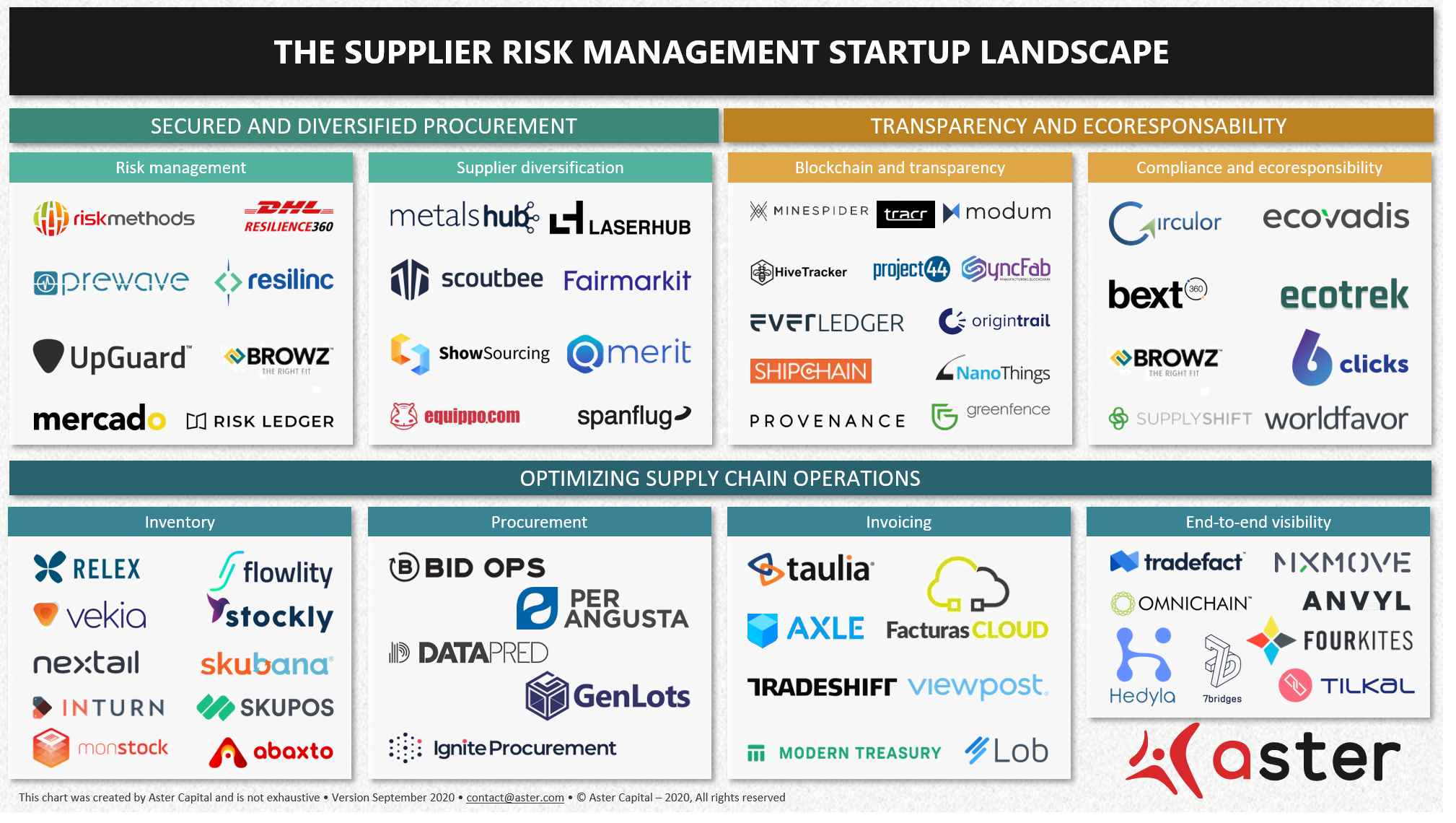

At Aster, we have taken a closer look at the field of supplier risk management in large-scale industry and manufacturing and identified 3 areas where startups are flourishing:

- Procurement diversification and risk prediction. As supply chains are increasingly global and complex, companies are using advanced analytics and risk prediction platforms to mitigate the risk of supplier failure and ensure business continuity in the event of a shock. B2B marketplaces are also expanding to diversify sourcing.

- Supply chain management optimization. AI, advanced analytics, IoT and blockchain technologies are massively disrupting supply chain operations, from planning and inventory to customer service or back-office tasks. Automation and digitization are gradually enabling companies to improve supply chain efficiency, increase service quality, decrease operational costs, and need for safety stocks.

- Transparency and eco-responsibility management. With stricter environmental, social and sanitary regulations and higher customer expectations, a CSR framework needs to be integrated into supply chains. This is boosting the demand for tools that enable stakeholder authentication, regulation compliance, environmental impact measurement and supply chain end-to end transparency.